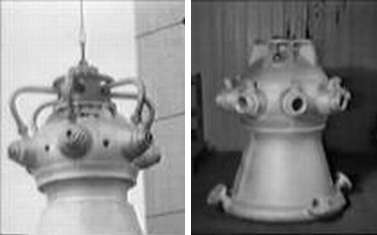

The "Ofen" development with common mixing head

-- and with use of Diesel-oil + Nitric Acid propellant

--

for the Aggregat 4 (A-4), series C

Source: Thomas Kliebenschedel,

www.V2Werk-Oberraderach.de

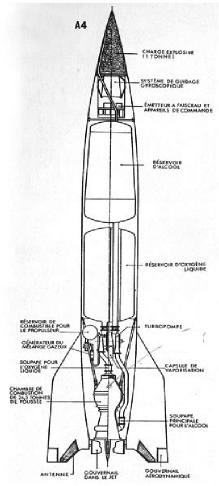

Further to the first prototype of the aggregat 4 were produced two series: Series A as a pure development vehicle and the series B for use as a weapon. The development of the series C was to follow. The fuel injection system of series A and B of A-4 consisted of a cluster with 18 single mixing heads, which were arranged on a combustion chamber. The planned series C should have a common mixing head. It also was the intention, the A-4 alternatively from Alcohol + LOX propellant completely convert to Diesel-oil + Nitric Acid operation.

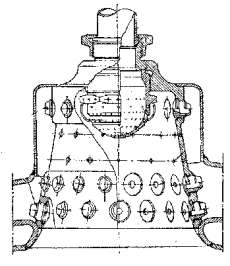

The new common mixing head on the combustion chamber consists of a large centrally-mounted injector plate. The injector featured a circular slotted plate with holes arranged in complex radial, parallel and circular patterns.

Based on a better atomization and mixing of the fuel in the combustion chamber was expected a pressure of 40 atm, opposed to 13-14 atm in the 18 mixing head "Ofen". The higher pressure would mean, lower fuel consumption as well as longer burning time and 270 km reach more.

With the use of Diesel-oil + Nitric Acid, instead of Alcohol + LOX, based on first calculations, was expected a reach of 430 km, later up to 550 km.

After examination of the initial considerations, the A-4 to fuel with the increase weight of Diesel-oil + Nitric Acid propellant, it was extrapolated that the A-4 in the launch phase had to low initial acceleration. Therefore should the construction of the A-4 rocket to be changed, and then a 40atü 300 kN "Ofen" as standard engine get.

In 1941 the engineers began to develop the new "Ofen". First was used the propellant Visol + SV.

Visol:

Isobutylvinylether + Anilin

SV: 10 % Sulfuric Acid + 90 % Nitric Acid

On Aug. 25, 1941 the first time a common

mixing head "Ofen" burned on the test stand. A pressure of 10 atm and a thrust

of 40 kN were measured. A common mixing head "Ofen" with 40 atm and 400 kN thrust

was in the building.

Planned for the A-4 of the series C was a switch to alternative materials. This

was not realized, because the common mixing head “Ofen” not the production line

had reached. Instead of common mixing head “Ofen” was the 18 single mixing head

“Ofen” -- it was manufactured in the A series by aluminum -- used in the B series

but of steel. This was not screwed now but welded with the combustion chamber.

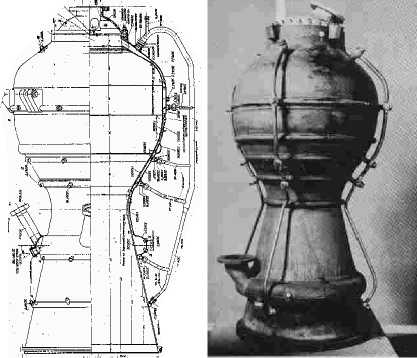

Early "Ofen" with 6 single mixing heads (per 15 kN thrust).

A precursor for the later 18 single mixing head "Ofen" (270 kN)

for the A-4, series B

Single mixing head "Topf" for A-4, series

B

As propellant was chosen Visol + SV (10 % Sulfuric Acid + 90 % Nitric Acid) was widely distributed in the explosives industry and available in sufficient quantity.

Visol (Isobutylvinylether + Anilin) is a byproduct of the fuel-distillation (coal liquefaction).

A small common mixing head "Ofen" in Peenemünde was found. It documented the modest end of the development in Germany.

Post the WW-II the engine of the "Wasserfall" anti-aircraft missile in the U.S.A. for the sounding rocket "Viking" was used. It is named XLR-10-RM2 and produced 93 kN thrust. The propellant was Alcohol + LOX.

Future combustion chamber for the A-4, series C

The new common mixing head on the combustion chamber consists of a large centrally-mounted injector plate. The injector featured a circular slotted plate with holes arranged in complex radial, parallel and circular patterns.

Planned A-4, series C